رسالة على الانترنت

رسالة على الانترنت

المزيد من المعلومات

المزيد من المعلومات

2024.2.8 productivity and OEE of the rolling mill division in a steel plant located in central India by employing TPM and SMED methodologies. This study will provide

Read More

One of the largest enterprises specializing in the production of high-performance high-speed steel series products in China. OEM for BRC. Long-term supplier for Gerdau.

Read More

LAMINATOI SERIE LM. The LM-series rolling mills are available in three different dimensions, each of them with specific features: LM160 rolling mill for a middle-sized

Read More

A STEEL. “On September 10, 2015, in the rolling process of the steel rolling mill, the LMMGROUP high-speed steel bar rolling experiment was carried out on the first bar line

Read More

2022.9.20 Fig 2 Rolls and types of rolling mills. Besides normal rolling load and the frictional forces, rolls experience several changes in the rolling conditions under normal

Read More

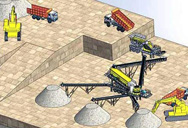

Casting rolling mill is typically 2 high hot mills capable of providing consistent thickness strip from hot cast incoming material. This process of reducing material to the desired thickness while still hot allows for the most

Read More

2.1 Experimental set up. A Hille-100 rolling mill with rolls of 225 mm diameter and 254 mm length, driven by a variable speed DC motor of 75 horse power, was used. The maximum

Read More

6 天之前 Rolling mills are machines that shape metal by passing it through two rolls. They are used to flatten and reduce metal to a sheet or plate. Most rolling mills feature two or

Read More

Professional Rolling mill rolls manufacturer with 20 years of production experience. Cast steel iron rolls, forgent rolls, work rolls, backup rolls, hss rolls. mainly produces all kinds

Read More

2017.8.11 a Loesche mill, with a grinding track diameter of only 1.1 metres, was used as long ago as 1935. However, the breakthrough in grinding this type of material on the vertical roller mill did not take place until the beginning of the 1990’s. 1935 The first Loesche mill for grinding cement clinker, an LM 11, was commissioned in Joao Pessao, Brazil.

Read More

2020.7.13 A function for computing the rolling and expanding linear models of time-series data. roll_lm: Rolling Linear Models in roll: Rolling and Expanding Statistics rdrr.io Find an R package R language docs Run R in your browser

Read More

2023.12.14 The variable gauge rolling process entails fluc-tuation in external load, in form of rolling force, and variation in stifness of the vertical system of rolling mill. The dynamics of the rolling mill under these conditions directly afect the stability of variable gauge rolling process. Therefore, the primary objec-tive and significant ...

Read More

2023.5.31 Your Capacity and Production Requirements. The first step in selecting a rolling mill is assessing your production requirements. Determine the desired capacity and volume of steel you need to process. Consider factors such as the thickness and width of the steel sheets or bars and the desired output speed.

Read More

2001.10.1 The largest LOESCHE mill so far is the LM 63.4 with a table diameter of 6.3 m and a capacity of 840 tIh cement raw material at 85 % P 90 !lm and with an installed power of up to 6 MW (Brundiek, 2000). In the LOESCHE mill, interparticle comminution takes place in a material filled gap between the rotating flat grinding table and the conical ...

Read More

2001.1.1 The application of oil lubrication in hot strip rolling has many advantages for the process, i. e., reduced roll force, reduced energy consumption, better strip surface quality, and reduced roll wear.On the other hand, oil lubrication may also induce severe disturbances for several control loops in a tandem hot rolling mill, which can reduce the

Read More

XINKE HEAVY MACHINERY has built more than 300 steel rolling production lines for many customers around the world. Plus, w e also have invested two (02) x 1,000,000TPA hot rolling mill production lines by ourselves.

Read More

2021.4.1 The simulation results show that the thickness oscillation can be manipulated with high accuracy by using NARMA-L2, since it can remove the non-linearity of servo system and other disturbances ...

Read More

Conventional Mill Rolls. Professional Rolling mill rolls manufacturer with 20 years of production experience. Cast steel iron rolls, forgent rolls, work rolls, backup rolls, hss rolls. mainly produces all kinds of metallurgical rolls for various types of steel, bar, high-speed wire and strip hot and cold plate and strip rolling mills.

Read More

2024.4.5 Vietnam. Vertical Roller Mill. 0. For the greenfield project in Thanh Thang LOESCHE will supply two vertical roller mills type LM 53.3+3 CS.

Read More

The 18-stand ultra-compact rolling mill featuring two 6-pass, fast-finishing blocks will roll rebar ranging from 8 to 40 mm dia. Danieli MIDA QLP minimill is the benchmark technology for commercial production thanks to

Read More

4 天之前 Since 1906 worldwide market leader in designing, manufacturing and servicing vertical roller mills for the cement, power and industrial minerals industries. Plant engineering solutions for any mission Loesche

Read More

A comprehensive portfolio of solutions for the hot rolling of bars, coils, sections and rails. An expertise enriched by the historical brands of Pomini, Ashlow and GFM. A profound knowledge and understanding of the processes. A relentless pursuit to improve and innovate the technologies. A scorecard of more than 500 completed installations. 500.

Read More

The LM-series rolling mills are available in three different dimensions, each of them with specific features: LM160 rolling mill for a middle-sized workshop with a ... Compare this product Remove from comparison tool. See the other products CHINETTI. four-high rolling mill. steel with coiler.

Read More

Head Office Address. Address : Plot No. 70, Sec - 25, Ballabhgarh Faridabad, Haryana, India 121004. Phone : +(91)-129- 4181100

Read More

2022.8.10 The finishing mills are composed of 5 to 7 consecutively arranged stands and coilers. Hot strip mills are named according to the length of the roll body, and those with a length of more than 914mm are called wide-band steel mills. The length of the work roll of the finishing mill is 1700mm, which is called a 1700mm hot strip mill.

Read More

Three-roll reducing and sizing mill. The ESTK three-roller sizing unit is equipped for the final rolling process of rolled steel bars and is used to produce high-precision and high-quality round steel, hexagonal steel, etc. 1. The rolled round steel products have high dimensional accuracy and fully meet the 1/6DIN10060 tolerance range for ...

Read More

3 天之前 Runhao partner network. RunHao machinery specializes in providing comprehensive solutions for hot rolling mill, including heating furnaces, continuous casting machines, continuous casting and rolling equipment, auxiliary equipment, rolling rolls, and hot rolling mill accessories. Register here.

Read More

Product description. The 4-high mill is equipped with positive and negative work roll bending in order to influence the shape and the flatness of the strip. Either the work roll or the back-up roll is driven, depending on customer requirements. The diameter of the 4-high work rolls amounts to approximately 1:4 in relation to the barrel length.

Read More

Long-term supplier for Gerdau. Certification:ISO 9001, ISO 14001 and OHSAS 18001. Annual capacity: Cast rolls 30,000 tons/year;Forged rolls 5,000 tons/year. Main technical staff and key workers are with over 20 years experience in roll industry. LMM GROUP main products focus on the cold and hot plate wide strip mill rolls and heavy section ...

Read More

2017.8.12 The latest information about our over-seas companies is available on our homepage loesche. Loesche GmbH Hansaallee 243 40549 Düsseldorf, Germany Tel. +49 - 211 - 53 53 - 0 Fax +49 - 211 - 53 53 - 500. E-mail: loesche@loesche loesche.

Read More

ROLLING MILL翻译:轧钢厂;轧钢机。。 The cast metal from the twin-belt continuous casting machine is synchronized with, and directly fed into, a hot rolling mill.

Read More

Here are a few of the main types of rolling mills: Continuous rolling mill. Sheet metal passes through several rolling stands, each pressing the metal thinner. Cluster rolling mill. A cluster of metal rolls are lined up to be thinned out. An example of a cluster rolling mill would be a 20-High Cluster Rolling Mill.

Read More

A special feature of Sundwig S6-high rolling mills are the side-supported work rolls. The patented Sundwig S6-high side support stabilizes the work rolls in this type of mill stand using mechanical, hydraulic lateral support equipment, thus preventing lateral excursion of these rolls. The diameter of the S6-high work rolls is only approximately ...

Read More

Lm S.s Rolling Mills Private Limited is a Private incorporated on 05 June 2007. It is classified as Non-govt company and is registered at Registrar of Companies, Delhi. Its authorized share capital is Rs. 6,450,000 and its paid up capital is Rs. 3,754,550.

Read More

2015.5.29 The rolling mill was modelled as a system of n inertial masses coupled by n - 1 torsional springs as shown in figure 1. In addition, linear damping proportional to the angular velocity was assumed. This leads to the system of differential equations (1) ... [lm, allows us to calculate m1.

Read More

The rolling mill experimental platform mainly consists of a driving motor, a reduction gearbox, a planetary gearbox, a load motor, a four-high rolling mill, two vibration exciters, and related control parts. Download : Download high-res image (551KB) Download : Download full-size image; Fig. 12. Experimental platform of rolling mill.

Read More

Home POMINI Long Rolling Mills. Un portafoglio completo di soluzioni per la laminazione a caldo di barre, matasse, sezioni e rotaie. Una competenza arricchita dai marchi storici di Pomini, Ashlow e GFM. Una profonda conoscenza e comprensione dei processi. Una ricerca incessante per migliorare e innovare le tecnologie.

Read More

2000.1.1 sources the use of lubricants in the hot rolling process. reduces the power consumption and the rolling loads by. 15±25% and increases roll life from 20% to 40%, whilst. Russian workers report ...

Read More

المزيد من المعلومات

المزيد من المعلومات

حقوق حقوق التأليف والنشر: رقم التدوين Development Buide 10200540 -22. خط الخدمة: 0371-86549132. E-mail:[email protected] العنوان: الرقم البريدي رقم 169 Second Avenue Avenue New Avenue: Chengzhou الصين: إحصاءات الموقع الشبكي 450001.